The hammer is one of the most basic and familiar tools. It can always be found in the garage, in the trunk of your car and in any construction shop. The hammer is considered to be one of the oldest tools that we still use in everyday life – because it has been used for over 3 million years!

Its main function is to hammer something – nails into the wall, beams in the construction and so on. Probably there are no adults who never had to hold a hammer in their hands. But if you think it’s a simple tool, then you’re wrong. There are many types and kinds of hammers, and what they are intended for – these are the topics we will try to cover in this article. In total, there are 2 large categories of hammers – Hand-powered and Mechanically-powered.

1. Hand-powered

The very first association that comes to mind with the word “hammer” is a hand tool. You take this item in your hand and can hammer anything you want with force. It would seem that this simple tool doesn’t have many different features. It turns out that even hand-powered hammers have many varieties. You should understand their categories and types.

1.1 Metal-Work Hammers

Special tools are required to handle dense materials such as metal. It is even necessary to take into account the fact that each of the metals has its own peculiarities – both in processing and in the structure. The chemical formulas and compositions of each type differ from each other and, accordingly, the instruments for working with them have to be special.

Raising Hammer

In the case you need to round up some parts of a metal object, or you want to make a recess in a metal sheet, the best solution is to use raising hammer.

This tool, as you can already understand from its name, is designed to give a rounded shape to objects – the creation of pits and notches, the creation of cylindrical shapes. If you have already imagined a hammer with rounded heads, you are mistaken.

The tool has rectangular ends on both sides, and the roundness of the shapes is achieved by hitting this hammer against a metal stake, by which you control the final result.

Forming Hammers

This tool looks just like you imagined in the previous version. The Forming hammer has rounded ends, which are designed to form cups and vases from the inside.

Such a tool is rarely found in a normal construction shop, mostly all of which are sold in specialized locations. Also, its shape can match the shape of the object that you process. In any case, forming hammers work exclusively with metals and give them a neat curved shape.

Planishing Hammer

This type of hammer is one of the oldest in its use. At first planishing hammer was used to create equipment for medieval knights. The craftsmen used a special stake, which was used for strikes. The appearance of the planishing hammer can be different – usually it is a striking surface, rounded on one or both sides.

Today, it is rarely found in use. But even if it is found somewhere, it is now a more mechanized model. It is activated by a pedal. The craftsman presses it with his foot, the hammer comes into action, and since both hands are free, the person can freely guide the sheet metal in the right direction.

But still more habitual in understanding under the term “planishing hammer” remains the usual model together with a stake. Nowadays it is a finishing hammer, so usually with its use the last touches are made in the polished surface.

Creasing/Bordering Hammer

This hammer is considered to be an excellent creasing hammer. Basically Bordering Hammer helps to create folds, bends or notches on metal sheets. When the finished product needs to be processed, Bordering Hammer is ideally suited to work with the border or edge of plates, bowls and similar products similar to bowls.

This tool has a very specific shape – the thickest part is at the point of connection with the handle, while the hammer itself tapers to the edges. You can even say that the shape of the face is like a wrong or cut off triangle.

Most often, the work of Bordering Hammer is the first step in the process of working in the lifting technique. Essentially, you specify a “drawing” for subsequent processing: the bending edges, the main contour or the curvature of the metal.

Embossing Hammer

Looking at this model, you might think, “We’ve already examined something like this!” Yes, you’ll be absolutely right. Embossing Hammer is similar in shape to some of the hammers discussed earlier.

It has rounded ends that are slightly larger in diameter than the base of the hammer itself. These “balls” are of different sizes on both ends of the hammer and, of course, both are used in the work.

The main function of the Embossing Hammer is to give the metal an “elevation”. This is achieved by hitting the material from behind, similar to repoussé. If you use this tool in the machining of finished products, for example, in cup-shaped objects you can strike from the inside, thereby lifting the outer surface.

When choosing the size, consider the dimensions of the edges of the hammer ends themselves. Depending on your goals, you can even use the embossing hammer for planing.

Chasing Hammer

In addition to the unusual working shape of the tool, the Chasing hammer also has a non-standard handle. The handle of this type of hammer is wide at the end, in some cases even spherical, and the handle is narrowed to the attachment. It turns out that the narrowest part of the handle is at the point of intersection with the base of the tool.

What about the shape of the hammer? There is a large flat washer at one end and a ball at the other. Both sides are designed for finishing work with metal. The shape of the tool grip makes it easier to work with the tool, reducing the kickback and tiring the master’s hand much less when hit. The Chasing hammer is mainly used for small finishing jobs as well as for small metal parts. This tool is designed exclusively for decorative work, not power work.

Riveting Hammer

The purpose of this tool is clearly reflected in its title. As you could already understand, Riveting Hammer works only with rivets. Its main purpose is to shape the rivet heads. That is, from a small ball blank Riveting Hammer makes a whole hat, which can then be used as a full-fledged object.

The shape of the tool can be of two kinds. First, the form of one side is mandatory. It is pointed and rectangular on the cut. This wedge-shaped shape is used just to shape the rivet heads.

While the other side is simply flat, round or square on the cut. It serves its purpose – it specifies the shape of the rivet. It is ideal for refining. In general, ordinary people can confuse it with a standard hammer and successfully use it as a general purpose tool.

Goldsmith’s Hammer

The name already shows the sphere in which the tool is used. Yes, indeed, Goldsmith’s Hammer is designed to work with precious metals, in particular gold. Soft texture of precious metals requires some peculiarities in their processing, and, of course, special tools.

One end of Goldsmith’s Hammer is wedge-shaped (as with many models of hammers designed for metal finishing works), and the other has a round and dense surface. This end looks like a kind of rivet, which is attached to the tool itself. Both sides of Goldsmith’s Hammer are balanced and easy to work with. The hammer itself is lightweight and therefore suitable for working with soft metals. Basically, it is easy to forge precious items with the help of this hammer.

Cross and Straight Pein Hammer

Such hammers are very rare in domestic use, as well as they are quite difficult to find in conventional shops with tools. They can be absolutely different in weight, depending on what they are designed for. The heavier models are designed mainly for use with metals. The strength of the tool head also depends on its weight.

The main common feature of Cross and Straight Pein Hammer is that one side is always shaped like a bell or head. The shape of the opposite side depends on the type of tool – it can be both cross and straight.

Usually Cross and Straight Pein Hammer is used in forging, because after their use the cost of the product increases several times. Forging steel or iron with these tools changes the material beyond recognition. Processing is carried out mainly by the wedge-shaped end of the hammers.

Ball Peen Hammer

The Ball Peen Hammer can also be found under the names of an engineering or mechanical hammer. This type of tool is quite recognizable, often it does not cause a certain association in metalworking.

The shape of the tool is one rounded surface that is compacted and the opposite side is a flat surface. The round head of the hammer is designed to give the metals a shape. Easy forging simplifies the work with metals, and the special spherical shape of the head allows you to create a head rivets, harden them and steel tools.

Yes, it is the hammers of this shape that have long been used to harden the material. In addition, the Ball Peen Hammer can also be used to align the shape of small rivets and metal pins.

1.2 Carpentry Hammer

The most common use of hammers is carpentry. Creation of furniture, construction, small repairs – mainly the work of a carpenter is connected with hammers. As it turned out, even a separate type of work has its own nuances, which are taken into account when choosing tools.

Claw Hammer

You’ve probably used a claw hammer at least once in your life. This is the most standard tool for nailing. As the most basic tool for carpentry work, the claw hammer has two most common varieties.

The first is the head, and on the opposite side is a curved claw-shaped part. The second type has a straight claw-shaped part. In any case, this part of the cloth performs one function – removal of nails. The nail is placed between the 2 claws of the hammer and pulled out of the wooden surface.

Typically, the handle is slightly rubberized, which reduces slippage during operation, and the handle itself is centered relative to the head. But nowadays, a slightly modified claw hammer has also been developed – its handle is partially shifted in relation to the center of the handle towards the impact part, which makes it easier for the carpenter to strike.

Trim Hammer

Trim hammers can easily be confused with claw hammers by inexperience. They are really similar: both have straight claws, a smooth surface and a comfortable rubberized handle (note that the claws can also be curved). But unlike its “brother”, the trim hammer is much more comfortable and smaller.

Due to their lower weight, these hammers are better suited for neat and precise work, and are mainly used for nailing on deck or rail on stairs and ships. A small handle increases the accuracy of the impact.

Due to its short length, the trim hammer is designed for point and small, neat work. You can even say that it is better to use this hammer for finishing. All because the tool has a smooth nailing surface, which means it does not damage the material surface when working.

Framing Hammer

Framing hammers are mainly designed for work during the construction of wooden houses, in particular their framing. The heads of such hammers can be made of steel or titanium, and titanium models are slightly lighter in weight. On the whole, the construction is a long, heavy-duty handle that is ideal for driving large nails into large wooden or lumber parts.

Models with titanium heads reduce the pressure on the craftsman’s hands without losing their effectiveness. It is also worth noting the milled surface of the tool. Usually it is executed in the form of a wafer-like lattice on a head surface. This ensures that the tool will not jump off the nail head at the time of impact. Of course, this “pattern” slightly damages the wooden surface when working, but on large frames or houses it is not a problem.

The claw on the opposite side of the hammer head allows you to either bifurcate the lumber or remove nails from the surfaces. The wooden handle of framing hammers is usually smooth and sturdy, which makes the tool durable.

1.3 Bricklayers Hammer

Stones, concrete and masonry are incredibly dense materials that are almost impossible to destroy on your own. Molecules of these materials are special, and work with them is difficult and requires considerable effort. But people have found a way out and developed special hammers that are suitable for working exclusively with stones and rocks.

Geologist Rock / Prospector Hammer

A hammer designed specifically for professionals. Geologists and researchers use it in field geology to obtain fresh rock samples. Collection of fossils allows to find fresh rock, to study its renewed composition, layers and environmental impact. At the same time, they destroy rocks and help in the detection of fossils.

Geologist’s hammer has a standard hammer structure. Two heads, but different in size and structure. One side has a flat and square head. The other side is a chisel, flat and pointed. It is longer in size than the first part of the head. The flatter side is usually used to hit a rock to destroy it. The sharp side is designed to work with hard rock because the sharpest part is the most effective in breaking rocks or widening cracks. The head itself is made of hardened steel and the handle can be made of completely different materials.

The impact force depends entirely on the size and weight of the hammer. The shape of the handle determines the ease and efficiency of use of the hammer for the researcher, so the choice of instrument must be made wisely.

Brick Hammer

Brick hammer is known as Stonemason’s hammer. No matter what you call it, you will find a variety of geologost’s hammer under those names. This tool is used when working with stones and rocks.

The appearance of the Brick hammer head is a flat head and a knife that looks like a cutter. The knife can be either long or short, depending on the preferences of the user. Usually such a hammer is used for cutting small pieces of stone, processing bricks or concrete masonry, as well as cutting any hard materials without using a special cutter. Geologists use the Brick hammer to collect rock samples, as it is convenient to use and does not take up much space.

Club Hammer

You will not be surprised if you know what a sledgehammer is when you see this tool in the picture. Although the club hammer looks like a sledgehammer in the photos and images, in reality it’s just a small imitation of the hammer.

Club hammer has a solid two-sided surface. The handle is made of durable resin or hickory, tightly attached to the head itself. The hammer head is a solid (relative to the handle) rectangle with slightly rounded edges in some models. Club hammer is used in construction together with chisel and other tools. Usually this happens when dismantling small parts and structures, masonry stripping as a miniature sledgehammer replacement.

If your profession is directly related to dismantling or masonry, you should take a closer look at club hammers. They easily fit in your suitcase, the main thing – do not forget about the means of safety, such as glasses, mask.

Piton Hammer

The tools used by climbers are usually diverse and take up a lot of space in people’s outfits. Since there can be many surprises at height, a professional should be prepared for anything. Rock climbers often aim to do more than just conquer the top – sometimes they collect new samples of rocks, attach new hardware, explore the surface, nature and birds.

Piton hammers can be found under the name rock-climbing hammers. They help climbers to install hooks at height, fasteners or fix large bolts.

The head of the hammer looks like part of a pick. It is asymmetrical with respect to the attachment to the handle. The handle is usually a metal and rubberized construction. There is a hole in the head that is usually used to remove old hooks. It is usually several times heavier than a handle, since it can be hollow. Many hammers can have interchangeable heads to extend the functionality of the tool.

Scutch Hammer

Scutch hammers have one or more grooves for securing the coupling or drove. Some of them can be double-sided Scutch hammers, therefore having two grooves at each end of the head. It is mainly used for cutting bricks, but it is not actually convenient.

Scutch hammers are not very precise to use, for better accuracy it is better to use a chisel. Hammers require more concentration and effort from the master, as they are used directly when working with the material.

Hammers can be of two types. The first type has an asymmetrical head – on the one hand there is a shock surface, and on the other hand – a chisel for better adhesion to materials. The second type is considered to be a two-sided Scutch hammer. Its head is symmetrical in relation to the attachment to the handle. It has cutters on both sides. Each of them has a slot.

This makes it possible to use an additional device in addition to the hammer itself. For example, you can use the chisel itself on one side and the drive mechanism on the other.

Sledge Hammer

The Sledgehammer can hardly be called a regular hammer. Although this tool is referred to as a hammer, it looks massive and bigger. If you do not take into account its size, the Sledgehammer is a standard hammer, which has a rectangular flat head and a solid handle, which is usually attached to it by welding. The handle is long enough compared to a solid head.

Due to its size, the Sledgehammer requires a lot of effort to get you to use it. Keep in mind that the more power you have to swing the tool, the harder you are going to impact. These models can weigh up to 9 kg, or even more. Such massive tools are mainly used to break down walls and materials – as they are designed to apply a large amount of force to one particular place.

In the past, Sledgehammer was also actively used in railway construction. With the help of massive and heavy tools, it was not difficult to fix the railroads in the right places, straighten the rails and much more.

1.4 Electrical Works Hammer

Working with electricity requires caution. Any incorrect movement can cause injury or even death. If you choose tools made of the wrong or unsuitable material, you may regret it. It is worth considering in more detail which types of hammers are suitable for electrical work.

Electrician Hammer

Electrician hammer is easily mistaken for claw hammer. Their main visual difference in size. Electrician hammers are more compact in design. In fact, there are many more key differences that make this tool suitable for working with electricity and wires.

Firstly, it is a handle made of fiberglass. It absorbs vibrations from shocks well and is also insulated. This protects the master or electrician from electric shock. Thanks to this, the work will be safe and efficient.

Second, the hammer head has two ends: one for removing nails and the other for hammering them in. The hammer head is flat and leaves no traces on the surfaces.

Lines Man Hammer

Electricians and people who generally work directly with electricity, wires and bare contacts need not only special uniforms but also special tools. One of these specialized tools is Lines Man Hammers.

It is worth noting the unusual appearance of the hammer. It is a rubberized handle, fully polished body, and often additional rubberized surfaces are found at the place of connection of handle and head.

Lines Man Hammers heads are rounded, although one of them can be straight. This shape is useful for nailing directly into poles and for those working on telephone and power lines. The handle is made of fibreglass and absorbs shocks and vibrations well when working on utility poles – nailing and bolting.

1.5 Special Type of Hammers

Hammers are not limited to standard tasks. There are many fields of activity where hammers can be used for absolutely improper purposes and are not related to repair or construction. These hammers are interesting to explore.

Gavel Hammer

We believe that you are surprised by this position in our article. Although the gavel hammer is not a construction tool, it is still a hammer that is used in everyday life. Indeed, because gavel hammer is used daily in court by representatives of the law.

The hammer itself is made of wood, usually has a shaped handle and a decorative head. Both sides of the head are symmetrical and identical. Usually it is lacquered, but not painted – in appearance the texture of the tree is preserved. The gavel hammer itself is a symbol of power and authority, only the chairman or judge can hold it and use it.

It is used, of course, not to build or hammer nails, but to amplify the sound and attract attention. They hit with a hammer on a special stand, thus demanding silence in court.

Reflex Hammer

At the neurologist’s appointment, you probably wondered why he had this “torture tool” in his hands. The Reflex hammer is a medical tool for testing tendon reflexes. It is used exclusively by practitioners when patients are admitted.

Usually, this tool is only available in medical stores or at the place of work (if you work in a clinic and not in a private practice). What do you check with a reflex hammer? The reflex hammer is a test for reflexes that can be used to detect disorders in the central or peripheral nervous system. The Reflex hammer can be for both knees and chest impacts. Don’t be afraid, all blows are easy and tightly controlled.

Neurologists usually hit the patient with a pre-distraction so that even a slight blow can become a reflex stimulator. The blow follows an arc-shaped trajectory and the instrument itself is easily held by the edge of the handle.

Welder’s Hammer

Welder’s hammer can sometimes be found under the name welding hammer and the nature of the tool does not change. It looks a bit dangerous – the hammer head has a pointed funnel-shaped end on one side and a sharp, flat head on the other.

They are mainly used for welding, specifically afterwards. One of the peculiarities of such a hammer is the loop, by which the tool can be suspended during the work.

The chisel is designed for cleaning pipes and small parts after welding from slag and dirt. Such hammer is not required for welders if they use wire welding machines. It already has wire and other tools for cleaning. Sometimes welder’s hammers come together with a cleaning brush. All welds are post-treated with a hammer after the welding spot has cooled down.

As everyone knows, high temperature is an integral part of welding. Since the craftsmen wear gloves, they often do not feel warm. In order to protect masters from a hammer fire, most tools are made with a steel spiral handle. On top of that, this makes it easier to impact the material during work.

Tack Hammer

It’s not always convenient to hammer small nails. It’s easy to miss, hit the wrong nail or hammer a nail at an entirely different angle. In order to avoid such mistakes, professionals prefer to use small tools. Such a tool is a tack hammer.

It is easy to use and lightweight. One of the most obvious examples of its use is the upholstery of furniture. If you have examined the frame of wooden furniture, you have seen the tiny nails that attach the cloth to the wood. This is exactly the kind of delicate and accurate work that tack hammer is designed for.

The design of this hammer is standard, just reduced in size. One side of the head is usually magnetic – for better nail grip or just to avoid losing small metal parts. The most common use is forged heads, because cast ones are much more likely to fail. You can use a plastic fastener in combination with this hammer. If you think that tack hammer is uncomfortable or useless, you can easily replace it with a building stapler.

Tools Maker Hammer

This tool is rarely found in shops or in the storeroom of masters. Tools Maker Hammer was actively used before to create new tools. It was often used by blacksmiths and metal craftsmen. Nowadays, such tools can be found only in the collections of amateurs.

The design itself is a cast tool, the heads of which are asymmetrical. They are different in diameter and size. Between them there is a magnifying lens, which allows you to observe the small details and their changes during the work. In order to prevent the lens itself from falling out during impacts, it is equipped with rubberized ribbon on the contour.

The design of the Tools Maker Hammer is lightweight and durable. Due to the fact that the tool is lightweight, it is very convenient to work with. The rubber edge of the glass reduces vibrations on impact. These hammers have a ball hardening, and the chrome surface makes the appearance more attractive. There is also a hole in the handle, by which you can hang the hammer.

Rail Road Spike Maul Hammer

The work of railroad workers does not come without the repair of railway tracks. Usually, you can find only metal heads on sale in shops, while the wooden handle can be purchased separately from the main tool. Rail Road Spike Maul Hammer is used for hammering out spikes on the tracks, as well as during the work on hammering and pounding of various crutches. It is also possible to hammer railway tracks with them.

The track hammer has a special shape. The ends of the tool are slightly pointed and hardened on both sides, usually the head is covered with lacquer. A special steel “skirt” at the bottom of the head is used to protect the wooden handle. This reduces the pressure on the tool handle and also reduces wear. Typically, the tool head is thin and long, and the handle is also long. This makes it possible to strike effectively on sleepers on the railroad tracks.

Boiler Scaling Hammer

Boiler Scaling Hammer, despite its highly specialized name, is not only used in boiler houses. In general, this hammer is used wherever strong and coarse cleaning is required as well as complete surface treatment. However, in terms of designation, it is best to use the Boiler Scaling Hammer to remove dross, deposits or slag from the metal surface of boilers.

The shape of the hammer head has both horizontal and vertical pointed sides. The head is rounded to the edges of the hammer. The sides themselves are shaped like a chisel. The Boiler Scaling Hammer breaks up internal limescale, which is accumulated in the production of metal barrels and boilers, as well as in the boiler rooms in the basements of houses and apartments.

Half Hatchet Hammer

This is atypical hammer, which is easy to take for a completely different tool. In addition to the name Half Hatchet Hammer, you can also find a shorter form, such as Hatchet Hammer, or rigging axe. As you could understand from the picture or the latest formulation, the Half Hatchet Hammer is a hybrid of an ordinary hammer and axe.

The head is shaped like an axe blade on one side (without the part of the axe where it is attached to the handle) and a more standard hammer head on the other side. Often the head, which imitates the “hammer” part of the tool, is a little rounded and smooth, which means that it leaves no traces on the material when hitting lightly.

Nowadays Half Hatchet Hammer is found in various types of construction. It can be used everywhere: in construction, in housework and in the backyard, in garden care. This hammer is perfect for survival kits or emergency suitcase with tools – as it is a hybrid of two useful items.

Drywall Hammer

It is worth noting that the drywall hammer is also a bit like an axe in shape. Only this time the hammer does not have an axe blade, just one of its heads is more solid and rectangular. This part of the hammer has a toothed surface that allows you to remove nails. The more standard side of the hammer head has a “waffle” pattern, which guarantees a stronger bond between the tool and the nails. This allows for better hammering into drywall.

The Drywall hammer mainly works with materials such as drywall. It can be used for both decoration and disassembly. The part that looks like an axe is usually used to cut the material, or to directly destroy it. The toothed, serrated part of the hammer head is more suitable for creating recesses, preparing the material for nails.

The main characteristic of the drywall hammer is its weight. Models can vary in weight, which means they can have different impact recoil. It is necessary to consider this factor at purchase. If you need to destroy a large part of the wall or material, you should give preference to the heavier and more massive drywall hammer models.

Dead-Blow Hammer

A specialized tool that differs from many hammers in its cast housing. The Dead blow hammer is designed to minimize damage to the impact surface and to reduce the recoil after impact. On top of that, it reduces the impact force required for use. In narrow spaces or with fragile objects, the dead blow hammer is a useful function to reduce rebound – so you almost eliminate damage that may occur elsewhere in the material or object.

The hammer body is usually cast, made of rubber, polyurethane or elastic plastic. Polyurethane tools are usually black or orange. The head can be solid or hollow, or partially filled with loose materials. This is exactly how it reduces rebound and distributes the force applied on impact. As the filled head can break down during operation, its uses are limited because particles inside the head can be scattered as a result of breakage.

Some dead blow hammer models exclude the handle from the design and some may have replaceable heads. Worn or broken dead blow hammer inserts can be easily replaced without buying a new tool.

You may also like: 30 types of saws

2. Mechanically-powered

Surely handmade work is more reliable. However, we all understand that it is difficult to cope with a large amount of work on our own – it is exhausting, takes a lot of time and effort. In order to speed up the work process or to improve productivity, mechanically-powered hammers are available. Some of them have their own features and differences.

Hammer drill

The Hammer drill is a power tool that has been designed to work with very hard materials. Sometimes you can find it under the name percussion drill. These hammers are equipped with a special impact mechanism. The impact mechanism itself is a sequence of short impacts on the material. This is a fast drilling tactic, however, if the impact mechanism function can be disabled, the tool can be used as a standard drill.

The hammer drills are equipped with a special clutch, which not only allows you to rotate the drill, but also to use it as a hammer. Although the chisel makes small and weak blows, their frequencies are quite enough to punch through the material. Hammer drills are not designed for industrial drilling, but for making small holes in hard materials such as concrete, masonry or bricks.

Such tools are always equipped with a special switch that enables or disables the coupling. Most often hammer drills are operated wirelessly. They are more cumbersome and expensive, but are best used in places where the wall material is unknown or consists of several textures.

High Frequency Impact Treatment hammer

Such hammers are usually used for post-welding treatment, in particular for the treatment of welded crossings. Thanks to this treatment, fatigue strength of welds is almost doubled. Welding time is extended by an average of 10 years, which saves a lot of money and time for masters.

The High Frequency Impact Treatment hammer can be used for both fresh joints and metal structures as well as for existing items. The hammer itself is a pin with a ball. This part of the hammer performs progressive impact movements with a frequency of 200-300 Hz on the welded pin. The changes in the seam and its deformation take the form of a High Frequency Impact Treatment hammer track.

In case you are wondering why there are no other cracks, seams or fractures in such a treatment, it is worth noting the other ability of this tool. The compressive residual stress does not allow the rutting to crack, thus eliminating the possibility of damage.

Jackhammer

The Jackhammer is a handheld portable tool. The drilling machine is driven by compressed air from an air compressor. The Jackhammer is connected to it by means of a special pneumatic hose. The design itself is a crushing chisel, which just does all the work. The entire tool is held in place by 2 handles placed on the end.

The chisel moves progressively up and down, crushing concrete, masonry or other materials. The Jackhammer is driven by an internal hammer, which also moves up and down. The Jackhammer is only used in a vertical position. Gravity holds the hammer in place and also helps to press the chisel into the material. With full-size tools it is recommended to work in 2 persons.

In practice, however, it is usually controlled by a single master who holds the Jackhammer in place by force. Of course, there is a less common model, which is not driven by an air compressor, but by hydraulics. It is larger in size and is usually installed on excavators. This type of hammer is used in the mining industry, where the strength of rocks and other materials is much higher.

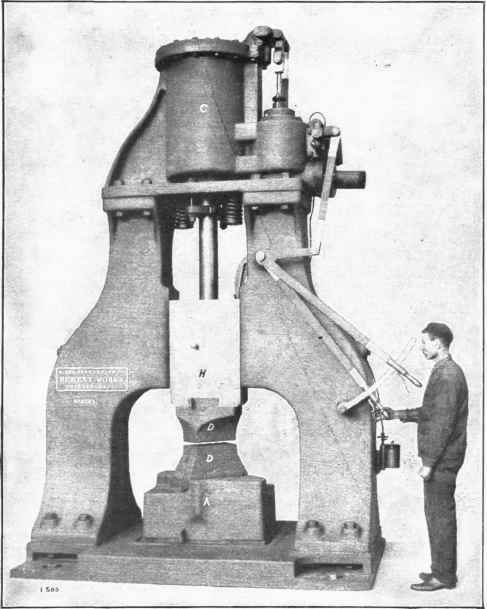

Steam hammer

Steam hammers is an essential industrial tool in some industries. These hammers are driven by steam. It is used for pile handling, hammering and attaching. Today, Steam hammers are well controlled with new enhancements – this is how the impact force of the tool is better controlled.

From the inside, Steam hammers are designed as follows: A hammer is attached to the piston and moves inside the cylinder. The hammer has a support frame which, together with the support mechanism, is attached to wooden beams. The double frame can hold a larger hammer. In order to ensure that the building itself does not shake when the Steam hammer is working, the reverse hammer system has been made.

The design of the hammer is such that the opposing forces suppress each other, which absorbs the rebound of the impact. Modern hammers can work in any mode and under any conditions. Previously, the impact force could be controlled by the amount of steam, but now it is done automatically. Nowadays Steam hammers can perform up to 300 impacts per minute, which provides an opportunity to work with any materials.

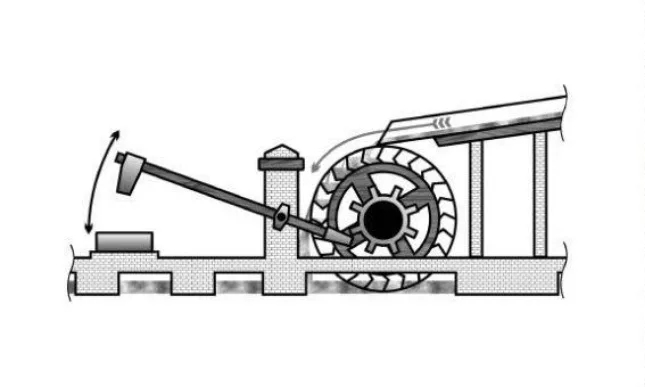

Trip hammer

Trip hammer is common on construction sites, demolition sites, or when redesigning houses and apartments. But their sphere of work is not limited exclusively to construction. For example, in China Trip hammer was used for a long time at processing of rice, and Romans extracted ore and other rocks with its help.

Such hammer uses gravity with the help of a lever. The lever raises a lot of weight, and when the hammer meets an obstacle, it lowers that weight. In general, all the Trip hammer does is lift and lower the weight. The impact of such a device is much more powerful and precise than a hand hammer, because the impact is mechanical.

Sometimes the Trip hammer is driven by a third party mechanism – with the help of teeth. For example, with a water wheel. Depending on the model of the hammer, a person’s participation can vary. The simplest Trip hammer can be simply unlocked manually, and the more complex models, massive in size and designed for large-scale work, have a more automated structure.

Hammers can be completely different. Depending on the purpose, scope, size and number of workers, they may vary in size and level of automation. Those types and models, which are designed exclusively for human work, are more easily accessible unless we are talking about rare professions and assignments.

Automated hammers are mostly designed for large construction or mechanized production. In any case, you can choose the right tool only after you have defined your goal. The variety of hammers allows you to look further than just one field of work.