Work in the garden, construction, repair and much more – sometimes we take on difficult work on our own. There can be many reasons for this – the desire to save money, a lot of free time, a trivial interest or even a hobby search. In any case, you will definitely need tools for all this. The first problem appears before you: what tools do you need?

For example, you may need saws. Depending on your physical abilities, the material you will be working with, the time you are ready to spend on the work and many other factors, the type of tool may be different. In addition to the fact that saws can be different in purpose and scope, they can also be different within each classification.

In order for you not to have to deal with this complex subject on your own, our experts will help you. After reading this article, you can even surprise anyone in the construction store with your knowledge – because now you know the topic much better than they do! So, get ready to study the 30 different types of saws that are available today.

1. Hand saw

Hand saws are not the most efficient in terms of performance. They’re just the most standard – you’ve seen them in your father’s garage since childhood, and these saws let children use them in their learning about tools. What kind of saws can you think of among hand saws? In fact, there are many different kinds of tools available! They can be different in their purpose, shape, material and many other things. Let’s take a closer look at each of them.

Rip Cut Saw

For example, if you’ve ever built a small building, or tried to build a tree house as a child, or just helped your father in a garage, you’ve seen this saw for sure. People usually call the Rip Cut Saw a standard hand saw. It is used for rough cuts, to frame a tree or simply to reduce the length of sticks.

Typically, the rip cut saw has about 5 teeth per inch, each at an angle of 8 degrees. Because the saw narrows in size as it gets further away from the handle, this helps it to move forward. The carpenters usually have several rip cut saws of different lengths in their arsenal for greater precision.

Back Saw

This is another hand saw, but with a slightly unusual design. Its cutting teeth are located opposite the stiffening rib. Normally, you cut with the bottom part, but back saw is characterized by the teeth at the top. This arrangement ensures that you have strict control over the cut and a higher degree of precision.

Statistically, these saws have a relatively small number of teeth and the distance between them is short. This limits the depth of cut. The back saw blade is very hard and thin. It would seem that these are two incompatible parameters, but they are achieved by spot welding of the hardness cap. Since the saw cannot cut deep, its specificity is slightly limited. Back saw is most often used, for example, for cutting boxes.

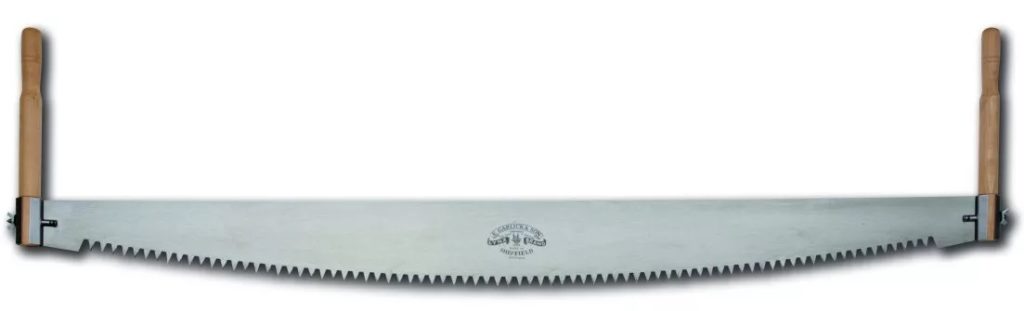

Bow Saw

Bow saw has a distinctive appearance. In fact, it is a cutting blade stretched over a curved frame. This type of saw is characterized by frequent transversal teeth and a thin blade. Bow saw is used for cutting wood, branches and small trunks. Usually, the diameter of such timbers and sticks should not exceed 150 mm.

If the material thickens, it is worth taking another type of saw – bow saw in this situation will be difficult to cope with. Some professionals may note that bow saws are like a hacksaw. Yes, Indeed: due to the accuracy of the cut, it can be used for rough cuts as well as for precise transverse cuts.

Coping Saw

Someone can easily confuse coping saw with bow saw, but these are two completely different tools. Coping saw has a thicker and coarser blade that creates conical seams. This saw cuts only in motion, and the accuracy and precision of the cuts is regulated by the tension of the cutting blade itself. If you need to cut a circle, create the most accurate cut or sharp bends, you will need to adjust the blade direction in relation to the frame.

The blade holding rods are tightly fixed to the handle and the tilt angle is adjustable with pins. All operation is effortlessly done with the thumb and index finger – so all control is possible during operation. The coping saw is suitable for woodworking and, if necessary, even for sawing aluminum pipes. It is worth noting that the efficiency is reduced by the thickening of the material.

Crosscut Saw

Crosscut saws are one of the most popular types of saws, which have many varieties for different purposes and materials. You’ve probably seen the saws in pictures or movies that should be used by two people at once. This is exactly what crosscut saws are.

In general, crosscut is a class of saws designed to cut wood perpendicularly. Depending on the type of work, the teeth of such saws also change – for finer and more precise work, the teeth are smaller and more frequent, while the coarse cuts are made with large tooth blades.

The reverse side can be slightly curved inwards to prevent the structure from bending during operation. Each cutting tooth is at an angle, so in general you can compare the work of the crosscut saw with the work of the knife – you can also apply a little pressure to cut through the material in motion.

Fret Saw

Sometimes Fret saws can be confused with bow saws, but they are actually two different types of tools. They look really similar – fret saw is attached to a curved metal frame. The blade is fixed with two nuts. The holding force can only be adjusted with a wrench – your hands or other unintended tools can hardly change the blade tension.

Comparing bow saw and fret saw with each other, you can immediately compare different purposes. Although bow saw can be used for fine work, fret saw is more suitable. The frequency of the teeth can reach 32 per inch, they are small and frequent. Fret saw has limitations on cutting length, but it is more useful for deep cuts and saws. You can make the most unimaginable curves and even right angles. The most convenient way to work with fret saw is to use a special table.

Hacksaw

Hacksaw is a C-frame saw with a thin blade stretched over it. A special screw mechanism is used to tighten the blade. Convenient use is provided by the saw handle, which usually looks like a pistol grip – there is a special place for fingers on it.

The teeth on the blades are small and sharp, as the saw itself is designed for metal cutting. They can be pointed in different directions, so that you can pull or push the tool while cutting. The teeth are quite rare or arranged in waves. Their arrangement depends on the material you are working with.

The steel blade is quite fragile – which is surprising because the main material is steel and iron. That’s why the metal alloy serves as a guarantee of durability and prevents the teeth from being blunted quickly. Sawing is usually a little wider than the thickness of the blade itself – this is one of the features of hacksaws.

Japanese Saw

Japanese saws are used far beyond Japan, despite their name. This kind of tool has some peculiarities, which are initially determined by the region of their invention. Since Japanese saws were designed to work with soft species of trees – such as cypress and pine, etc.

Due to the fact that the wood of these species has a special structure, such saws are cut not with the help of pushes, but exclusively on the traction. Since the traction has some features, the cutting blades themselves can be made much thinner – because the load on them is much less. Because you use a thinner blade, you get a lot less sawdust than with other saws. Accelerating your work also makes Japanese saws popular.

It is also worth mentioning the interesting feature of Japanese saws. Because their blades are incredibly thin, many people who use them prefer to buy disposable blades. The resharpening of Japanese saw blades is almost impossible – as their thickness does not allow for this.

Keyhole Saw

Keyhole saw is not the most standard saw in terms of appearance. In fact, if you’ve never been in the business of repairing yourself or just don’t work as a builder, you have never seen it before. It’s a pointed, narrow saw that looks more like a pike than a saw. It is used for cutting inconvenient or completely non-standard parts, creating holes in soft materials such as soft wood, plasterboard, plastic.

Modern models use a pointed tip in order not to use the drill once again – keyhole saw will do everything on its own. Different blades are attached to the saw handle. They can be completely different in number and frequency of teeth, with keyholes. The fixing is done with screws and the fixed saws are much cheaper than movable ones. Today, you can easily change blades for keyhole saws, depending on the material and type of work you want to do.

Pole Saw

Saws are not always needed for construction and repair work. Owners of country houses, cottages and houses in villages or suburbs need them especially. There are many trees in the backyard or garden that need to be cared for. Since you can’t reach the top branches on your own without help, you’ll need either a ladder or a long saw.

The Pole saw is a saw with an incredibly long handle, which you can use to cut off the upper branches. Typically, these saws at the end have either an incredibly sharp blade or a small chain saw or other mechanical variety. You control it from the ground, either by pushing it forward (thus using a standard hand saw) or by turning it on mechanically.

Usually the pole saw changes its length from 7 to 16 inches, not counting the length of the blade itself. The length must be adjusted on the handle of the tool itself. The cutting edge – the blade – is usually between six and eight inches long. You don’t need to hire a gardener, call in a special service or spend money on constant maintenance of your garden. In other words, you will be able to recoup your purchase in just a few times by cutting your own dry branches yourself.

Pruning Saw

When it comes to working in the garden, it’s worth remembering about bushes and small trees. You will need to take care of them as hard as you do with ordinary trees and plants. It often happens that a pruning shear or garden shears are no longer useful – branches and trunks have become too thick. In this case, you will need a pruning saw.

These saws have a long blade that tapers slightly towards the end. The handle often looks like a pistol grip with fingertip compartments. As it is designed to be stored compactly – for example, in a barn with other garden tools – many models come with scissors (for more thorough processing of plants) and a folding mechanism. The blade folds up, sometimes even comes with a safe attachment on the cutting surface.

The configuration of the teeth usually depends on the shape of the blade you choose. The two main types are straight and curved saws. The straighter the saw, the more uniform the angle of the teeth along the length of the entire saw. Amateurs and gardeners usually use pruning saws to work with green branches, dense knots. The thicker and denser your tree, the bigger the teeth should be on the saw.

Veneer Saw

Veneer saw is designed mainly for working with plywood, thin sheets of wood from 0.4 to 0.6 mm, veneer and other similar materials. It is not obvious from the appearance that this is really a saw. Usually it is small in size, has a raised handle and a slightly curved blade. The number of teeth on the blade can be different – an average of 13 teeth per inch.

The number depends on the purpose and the material to be worked with. Often, veneer cuts are made flush. This is also facilitated by the handle, which is often positioned right in the middle of the blade. The standard purpose of these saws is to cut small areas of veneer.

The saw blade is usually at least 2 inches long, often much longer. The average length varies from 3 to 4 inches. But it is important to note that the blade length is still not going to be large – the distinctive feature of veneer saw is its small size. In the beginning of work the veneer for cutting is placed necessarily on a flat surface, most often wooden. The ruler settles down on a line of prospective cutting, fixes and only then you can start work with veneer saw. This will provide you with precise cutting and accurate results.

Wallboard Saw

The Wallboard saw is a saw with a long and narrow sharp cutting blade. The teeth on the saw blade have been placed very often because the main work is done during the construction process. Wallboard saw is ideal for cutting drywall, sheet metal, chipboard and so on. With this saw, you get a clean and clear cut without any residue on the cut and without a lot of garbage.

Wallboard saws can be either double or single blade saws. Double saw models are more dynamic and faster in cutting – of course, because they have 2 cutting edges. Since these tools are durable enough, you can be sure that by buying an expensive option, it will serve you well for a long time. Most of the minor home repairs are limited to cutting drywall and plastic. Such models of saws are anti-slip, easily controlled without much effort.

Nowadays, the blade is made of hardened steel, which is not bent during work and is not blunted. Coarse cuts and neat cuts are made with a pointed tip. Handles made of non-slip material will only increase the convenience of use.

Plywood Saw

In case you have ever worked with a material like plywood, you know exactly how difficult it is to cut it without loss or unnecessary damage. Usually, the outside of the sheets is crumbling, rags and other unpleasant things appear. In order to make working with plywood easier, a special plywood saw had been designed. The final smooth cut is obtained only when working with this tool – to avoid wear and tear and spreading of the cutting edges.

To minimize material tears, the plywood saw has a thin toothed blade. The standard length is about 11 inches and the frequency of the teeth is about 14 by one inch. Sometimes you have to cut the plywood into small pieces (sometimes several sheets at once), you’ll need some tricks. Usually the sheets are placed somewhere on a flat surface and fixed for convenience.

For a smooth cut, only work with a well-sharpened plywood saw. Sometimes such a saw can even be designed in such a way that the sheet itself moves along the blade, not the other way around. Sometimes you can also use the plywood saw for coarser cuts. Then you’ll get the same neat cut, but you’ll have to do a lot more physical work than standard plywood or chipboard.

You may also like: 36 types of hammers

2. Power saws

We’re looking for efficiency these days. People value their time and do not want to waste it. It would be foolish not to mention the advantage of electric and gas saws over manual saws. They are more efficient, faster, more accurate and modern. But even seemingly trivial models differ from each other in appearance, functionality and purpose. It is necessary to examine them in a little more detail.

2.1 Portable saws

For those who are looking for convenience and functionality, portable saws are the right choice for you. They can be carried around, carried in the trunk and easily used anywhere. You won’t be restricted in motion or movement – this is an obvious advantage.

Chain Saw

Chain saw is the saw that looks most familiar to everyone who has ever encountered a chainsaw. Its key feature in design and appearance – the role of the blade is provided by the teeth attached to the rotating chain. These saws need fuel, otherwise they simply will not work.

When using the tool with earth, metals or stones, the blade becomes blunted very quickly. You may not even notice this at first. The sawdust from the trees will look like a powder, and it will take effort and pressure from you to cut. If the saw is in good condition and sharpened, the teeth go through the material themselves and do not require any force. There are different types of chainsaws for concrete and stones, so you should not use chain saws for any other purpose. Use with inappropriate materials can cause the teeth to fall off the axle and cause injuries.

There is also a danger when working with this tool. The suction filter may become clogged and cause malfunctions. So it is worth using the chain saw with proper equipment – at the very least, to protect your feet from sawdust with special trousers and boots, eyes with construction goggles or masks and so on.

Jigsaw

Basically the jigsaw is an ordinary electric jigsaw. What you used to have to do completely manually can now be done much faster with this tool. It consists of an electric motor and the saw blade itself (similar to the jigsaw blade of a hand jigsaw). If you change the cutting head, the functionality will also change. For example, if the saw blade has a mowing function, you will be able to create 45-degree joints at an angle to the vertical stroke.

Depending on the material to be worked with, there are also different blades for jigsaw. If you’re going to work with wood, you should use high carbon steel – it’s flexible and perfect for soft materials. For metals it is better to use high-speed steel or tungsten carbide – these blades will not be blunted and the bimetal saw blade is the most durable and versatile. Working with jigsaws requires a little patience and full compliance with the instructions. To get even cuts and accurate results, simply hold the tool straight without lifting it or taking it sideways while you’re working.

Miter Saw

Very unusual tool, which is not often perceived by people as a saw. Miter saw works with electricity, and its main function is to make precise cuts at a certain angle. The tool is used in the cutting or finishing of buildings and objects, because it quickly and accurately cuts corners. Typically, these are small, portable and easy to move saws, with blade sizes ranging from eight to twelve inches.

The electric saw consists of a spinning disc, base and main box. Depending on the purpose and angle of cut, there are several types of miter saws, both standard and rare. The standard miter saw is designed for the most basic cuts at an angle of 45 degrees (e.g. frame frames for windows and doors). A basic abrasive saw is used for cutting at 90 and 45 degree angles.

For finishing work, you can use either a complex miter saw or a two-component saw. They allow you to cut at angles different from the straight angle. Modern miter saws are equipped with safety clamps that can fix the workpieces. Also, the models have dust bags, which collect sawdust and other construction debris at work and many other things that will help you in your work.

Chop Saw

The appearance and working principle of chop saw is incredibly similar to miter saw. They also have a cutting disc that slips onto the material you work with. Although they are incredibly similar in design, they have many differences. The first thing you can notice is their size. Chop saw is much more massive, its cutting blade is at least 14 inches in size and its teeth are much more frequent and larger. The tool itself is powerful and incredibly aggressive – its cutting power can even impress. It is a massive and precise instrument.

Chop saws are available with a cutting wheel or with a cold cutting unit. This allows you to perform all work on the metal, cutting tires and beams, as well as fully cope with all building materials, which are usually used in construction. Even cutting pipes won’t be a problem. It is necessary to consider that different material of disks makes different cuts. The abrasive disc heats up the metal at the cutting point and sparks a lot when working, so you have to take care of the equipment and follow the safety rules.

In general, if you are not engaged in building a house from scratch or do not plan a major repair, then you will be satisfied with miter saw for small works. Leave Chop saw for professionals – the cost of this tool is high enough, and it will be a pity if it will just lie idle in your garage.

Circular Saw

Circular saws are one of the most famous power saws. They are powered by electricity or fuel, depending on the model. The circular saw is driven by a motor mounted inside the structure and cuts materials with a rotating disc. Circular saws are the most versatile in terms of the materials they will be working with. As the saw surface changes easily, so does the field of work.

Many manufacturers produce models with a metal cutting disc by default. But you will find saw blades for other materials in any construction shop or tool shop. Such saws can be used both “by weight”, keeping them on their own, and with the support of a stable surface. Usually, the material being sawn is held in a vise or fixed tightly on the surface, and the circular saw moves on, leaving behind a neat cut.

Cutting is carried out either by using the surface of the entire blade or by using the teeth located at the edge of the blade. The circular saw leaves a smooth cut afterwards, but there is one drawback: at the beginning and end of the cut, the tool leaves “burrs” that have to be hand-cut with sandpaper.

Track saw

Track saws are a kind of circular saw. You can also find another name – a plunge saw, and this is for a reason. In fact, the way track saw works is like a kind of immersion. The saw has a guiding base on which the tool usually rests. This base is placed on the material that you will be working on, and so that these two surfaces are in close contact. The cutting blade is protected inside the tool until the worker presses the lever or pulls the trigger – depending on the switch-on mechanism.

The saw is immersed in the surface at a predetermined depth and is absolutely safe for the person holding the tool – the blade on both sides is fenced off by the base. Usually there is a small ruler on track saws. It is designed to allow you to set the depth of cuts and sawing. So you will have to adjust the necessary measure every time – it is not fixed and depends entirely on you. Track saws have an undeniable advantage over circular saws – they do not leave any fibers on the sides of the cut, i.e. they do not destroy the material itself.

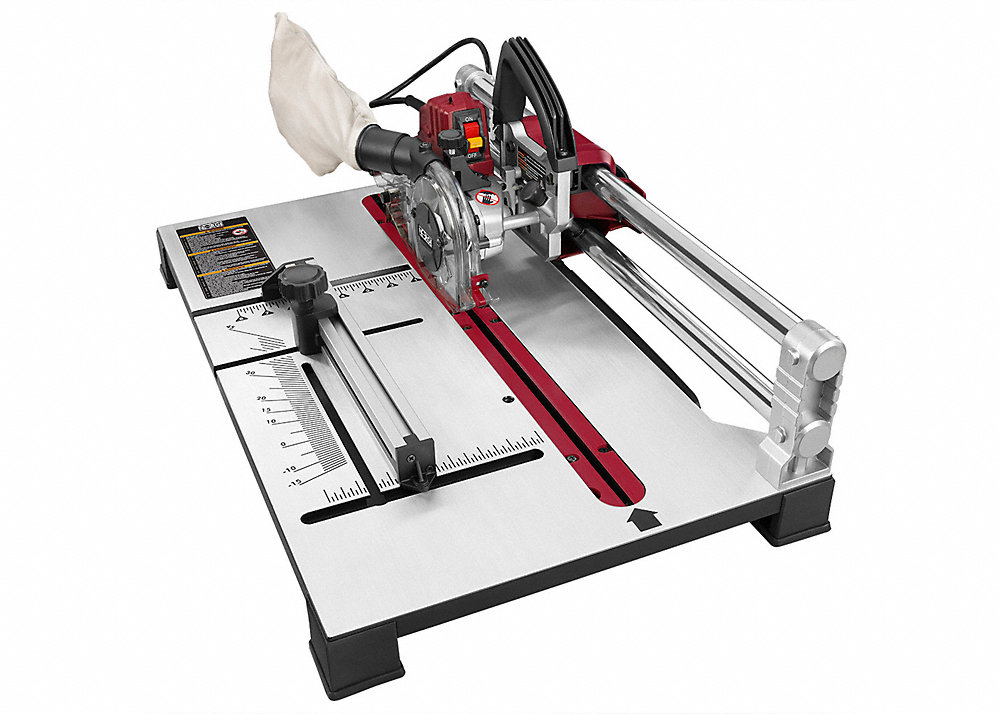

Flooring Saw

The name of this instrument speaks for itself. Indeed, flooring saw is designed to work directly with coatings, decking and flooring materials. The flooring saw is portable, handy and highly specialized. In fact, when you buy such a tool, you will not be able to use it for any other purpose – it will simply not be designed for this purpose.

Portability is the main advantage of flooring saw. To work with the floor covering you would need several tools at the same time – miter saw, hand saws and others. Flooring saws, on the other hand, provide you with the full functionality of several saws at once. You won’t have to run into the garage several times, take each tool and then take it back. Flooring saw leaves behind neat and clean cuts, minimal waste and sawdust.

The saw works with electricity, so it usually comes with a long cord. The design itself is a flat blade that fits snugly into the flooring material during work. Such a structure has long openings that allow for cutting. The saw blade itself moves inside these holes, guaranteeing a smooth cut and full safety for the operator.

Rotary Saw

Rotary saw is an innovative kind of saw that was developed not too long ago and is sometimes better known as “RotoZip”. The mechanical principle of the saw is mainly aimed at cutting drywall, siding, wood and plastic sheets and many other similar materials. The rotary saw works like drilling. The only difference is that when you drill, you get a hole, but this tool drills patterns and lines.

If you try to get a pattern with a regular manual or electric saw, you’ll have to create pilot holes first, because a standard saw just can’t create a pattern on a flat surface from scratch. With rotary saw you don’t need to use any other tools – it is equipped with a “bit”. You use it at the starting point of the cut and then simply follow the intended path of the pattern or cut. At the end of the sawing surface there are special guides that can be changed depending on the type of work.

If necessary, you can also change the saw blade itself – in this case it will be possible to work with metals and granite, for example. It should be noted that dust and waste can occur during the work – especially when working with drywall. It is worth to have protective goggles and protective clothing in advance – unless you want to get dirty.

Oscillating Saw

Oscillating saw operates on a pendulum principle. Usually these are small and fast vibrations – the deviation is only about 3 degrees, and the number of vibrations can reach 20 thousand per minute. This saw leaves you with a clean cut, so even if you only need a little finishing work, you can safely use it. In addition to the blade, oscillating saw can also use a sanding pad.

There are several basic types of saw faces for oscillating saws. If you need a cut like this when the blade cuts into the surface, it’s best to use a straight blade. Cleaner and neater cuts are made with a circular saw blade, but you will need to make a small notch before you start working. Bimetallic blades can be considered versatile because oscillating saws can work with almost any material.

When sparks appear during operation, it means that the blade is blunt and needs to be replaced. The new saw blades cut any material with ease. In addition to the main saw blade, the oscillating saw blade can also be equipped with a scraper. It is not a mandatory tool, but it is necessary if you expect to quickly and easily remove those items, dirt and dried glue that prevent you from cutting or dismantling any device.

Reciprocating Saw

Reciprocating saw is one of the most popular saws in construction. However, if you have already imagined the creation of something new after the word “construction”, you are wrong. Such a tool is designed primarily to destroy and dismantle materials, buildings and surfaces. The design often has a foot in the base, that can be relied upon. Usually it is designed to rest against the material you are working with – this reduces resistance and repulsion when cutting.

The saw blade makes cuts with reciprocating movements (in other words, pushes the blade forward and immediately returns it back). Sometimes there is also an additional orbital action – in other words, the saw blade moves to the right and left, thus creating “oval” cuts. This helps when working with the wood – the process is much more efficient.

The blades of the Reciprocating saw can be completely different and can be changed when working with certain materials. The most popular types are metal cutting blades, abrasive blades, drywall and wood blades. They can differ in terms of teeth and their quantity and blade material.

2.2 Stationary saws

Portable and transportable saws are not always effective. Often the amount of work is so large that the most efficient and productive tools are required. Unfortunately, these saws are massive or tied to a specific point or location. It will take some time and interest to understand their functions. So, we tried to analyze the most common types of power saws that cannot be easily moved from place to place.

Bandsaw

This saw is usually massive and it is not even immediately clear that it is actually a saw. A Bandsaw is an electric saw with a metal band with teeth on its saw surface. The band moves along a continuous loop, which is represented by several wheels (usually two or three).

One of the obvious advantages of bandsaw is its relative versatility. It can be used to make both curved and straight cuts. The main characteristic of bandsaw is the depth of possible cutting. Some models can adjust this value, but it is mainly fixed, so if you want to work with a very thick tree, it is worth choosing a model based on this parameter.

The only thing you can’t use bandsaw for in the woodworking is sawing of boards. By the way, it is worth mentioning that there are 2 basic types of such saws – floor and mounting. Mounting saws can be placed on a table or bench, while floor saws are more massive. Usually more massive models are used to create the largest furniture – cabinets, beds and cupboards.

Scroll Saw

The Scroll saw is an electric saw, driven either by electricity (directly by switching on) or by a foot controller. These saws are used to cut complex curves and joints, create sculptures and scrollers, and generally cut beautiful patterns that are difficult to create by hand or with other tools. Scroll saw has a thin-cutting saw blade that allows you to create the most accurate and delicate patterns. This tool is much easier to handle than a hand saw, and the result is much better.

The cuts and patterns themselves are the result of the reciprocating movements of the saw blade. Many Scroll saw models have a small flashlight or lighting on the spot where patterns and cuts are created, as well as a small “vacuum cleaner” to maintain cleanliness and remove any chips and sawdust immediately. Scroll saws are considered one of the safest tools. There is almost no contact between fingers and blade when working, so no injuries are possible when processing materials. Also, the special blades in modern models leave almost no chips on the lower edges of the material at the point of cut.

Table Saw

The name of this tool makes it look as if it is attached to a table at the workplace. In fact, this is not true: the table saw itself is a table that has a saw surface built into it. In general, it is a tool for woodworking, a saw blade that is attached to a support. The table saw is driven by an electric motor. The cutting itself is carried out using a blade that protrudes through the table surface.

The material is held by the cutting table itself. The cutting depth can be adjusted by moving the saw up and down. The saw blade can be raised to the desired height and there is no problem with the cutting of thick boards.

The Table saws are considered to be one of the most dangerous types of saws. There are several basic situations in which a machine operator can be injured. First of all, you should understand that you hold the material yourself and direct it to the saw blade. You can accidentally move the board so that the saw will be in dangerous proximity to your hands. Secondly, there is the concept of “kickback”. In this case, the disc may encounter an obstacle in the form of a torn piece of wood. The material simply bounces back to the operator, thus guaranteeing injuries. If the saw top is not made of metal, you should use an additional shield when working.

Nowadays there are 2 items that make working with table saw safer. This is a brake mechanism and change of the angle of the teeth arc. The brake mechanism in an emergency situation stops the saw and the teeth “throw” sawdust in the other direction from the operator.

Tile Saw

You may have understood from the name, tile saw is designed to cut tiles. That’s all. The only material this tool works with is tiles made of different materials. Since this is a very specialized kind of saw, construction stores often rent tile saws. Unless you’re a professional and a repairman on a regular basis, it’s just an expensive investment that you can use just a few times.

If you worked with tiles, you know that they are prone to defragmentation and can crumble and break if not used properly. Of course, you can cut the tiles manually, but with tile saw you will work faster, easier and more enjoyably.

The saw itself is a small worktop with a saw. Usually, the saw blade has a diamond coating, so that the cuts are made with the least loss, little garbage and so on. The dust itself from the tiles is dangerous for the lungs, and the diamond blade reduces the formation of this dust by several times.

The tile saw should be serviced in a timely manner. Even a slightly blunted saw blade can fail during operation, which can lead to injuries or material damage.

Radial Arm Saw

This is another relatively young kind of saw. It was developed less than 50 years ago and has been actively used even later. The design of the radial arm saw is a circular saw located and mounted on a movable horizontal lever. Like many stationary saws, the radial arm saw has a small table surface. The mechanism itself is driven by an electric motor – by switching on the saw blade starts to move on the horizontal lever above the table surface. Mainly its sphere of use is sawing long pieces of material, as well as cuts for dado, rabbet or half lap joint.

Unlike table saw, radial arm saw does not force the operator to move the material himself. You control the sawing surface while the material lies still on the table surface. It’s safer, but there’s still a risk if you’re an inexperienced operator.

Radial arm saw is easy to place in the garage or in any workplace. It can be easily attached to the wall and will take up much less space than many stationary saws. As these tools are made of stamped parts, they can be optimally used only after setting up. It is worth noting that a lever with a saw surface can move along all axes – except the vertical one. So if you have an idea of the settings you will need, then working with radial arm saw will not cause you any inconvenience.

Masonry Saw

The next type of saws, whose scope of work is clear from the name. Masonry Saw is designed to work with cellular concrete, bricks, stones and cement, as well as tiles (note that you should use specialized tools to cut tiles). Masonry Saw is the most suitable tool in the construction industry for cutting dense materials.

In appearance it looks like a radial arm saw – the saw surface is also attached to the lever, which is lowered on the material. The main difference in the saw blade itself is that it has its own special teeth, usually ranging from 1 to 3 pieces per inch. The tool is powered by electricity or an air compressor, depending on the type of work. There are two main types of material cutting – wet and dry. The most popular type of cutting is wet because it uses water to cool the blade and reduces the amount of dust that appears.

Since such massive saws are dangerous, it is worth mentioning it. Because of the nature of Masonry Saws’ work on solid materials, it can encounter even tougher obstacles and bounce back. Do not ignore the equipment: dust mask, protective clothing for body parts.

You may have realized that there are so many different kinds of saws. They vary in size, price, type and profession, and many of them are quite unhelpful for you. For example, you won’t buy a massive and expensive tile saw to cut 10 floor tiles, will you?

You may want to try each of these tools, so be aware that many construction stores often rent out tools, or you may ask your friends. In any case, the main advice we can give you is that there is a special tool for each type of work or material. Do not use non-specialized saws and saw blades – this can lead to injuries or material damage.